About Masterlube

Masterlube is a worldwide distributor of specialist grease and oil automatic lubrication systems, since 1976.

Masterlube are a specialist manufacturer of grease and oil lubrication systems for use in tough environments. Masterlube supply many of the world's top agricultural field equipment, mobile plant and heavy machine manufacturers, exporting to 20 countries.

Many operators spend large amounts of money each year on bearing and chain replacement, plus have to deal with a significant loss of production due to out of service machinery. Hostile working conditions and neglect of regular maintenance can be responsible for frequent breakdowns, lost production time and costly repair bills.

Why use an automated lubrication system?

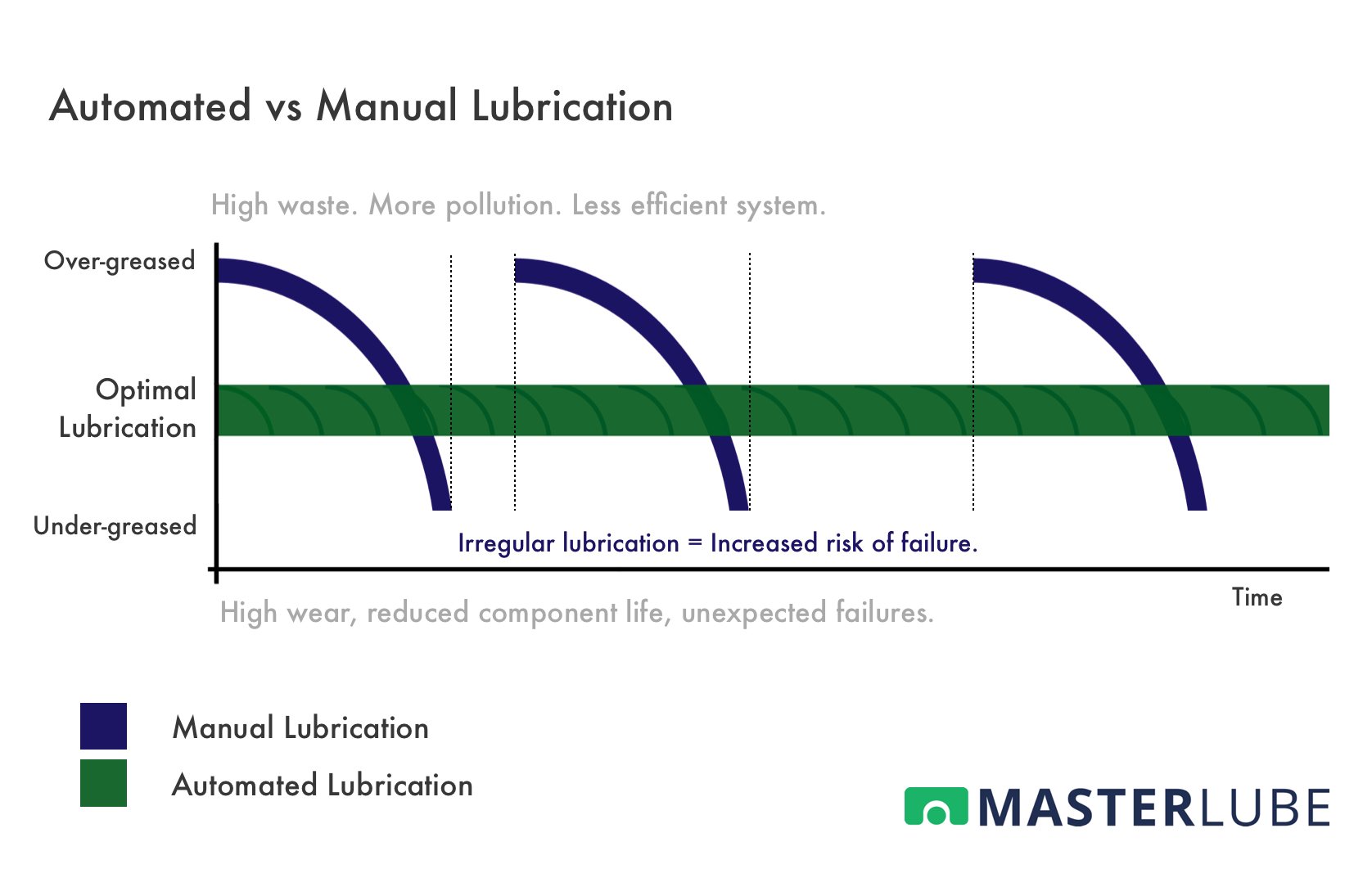

Anything which has a bush, bearing or gear; or for any component which rotates or slides, these require lubrication. While manual lubrication is still preferential in many applications, the use of an automated lubrication system is becoming the preferred alternative to minimise downtime, improve quality, reduce cost and improve safety for companies around the world.

- Reduce Downtime.

- Improve Productivity.

- Increase Profits.

- Create a Safer Working Environment.

Masterlube automated lubrication systems are able to provide continuous or regulated lubrication to any piece of equipment, component or system. Manual lubrication requires a person to manually apply a grease gun to every point during maintenance.

This has multiple benefits:

• Reduce the time interval between lubricant applications, which prolongs life.

• Saves a significant amount of time required for maintainance, especially for systems with large number of ports or access points. This allows the operator more time for other things and increases the time in service for a piece of equipment, increasing its profitability.

• Automated lubrication systems can be used in systems which are hard to access or pose a potential safety concern, such as onshore / offshore wind turbines.

• Automated lubrication prevents too much grease entering a system. Too much grease can increase the torque required to rotate the component, reducing efficiency in the bearing, gear or motor.

• Automated lubrication prevents the potential for loss of lubrication in the contact. Loss of lubrication can cause significant damage to a component (or part within a wider system) which can be critical to wider business operations. An automated lubrication is essential for reliable and optimal performance, whilst also reducing unexpected call-out charges due to failure.

• Automated lubrication systems also reduce the amount of waste grease, therefore reducing cost and also the effect on the environment.

Masterlube is part of the Bignall Group

Founded in 1976, the Bignall Group is a UK family run engineering company which has been successfully operating in international markets for over 40 years. What makes us special is the unique range of products designed, developed and innovated by the Bignall family. This innovation permeates across everything we do to make our client's world better.

Our Facility:

- 30,000 sq ft, 3.5 acre site in Shildon, County Durham, North East England

- 150kW Solar PV and Biomass System 620 panels, covering 1,200 sq ft

- Our Solar PV and Biomass investment provides cost savings and a lowered environmental impact of circa 80%, but also increases the environmental credentials of our customers.

Quality and Health, Safety and the Environment (HSE)

Quality and Health, Safety and the Environment (HSE) are the most important things to us as a business.

|

The Bignall Group are committed to conduct our business in a responsible and compliant manner at all times ensuring we protects the health and safety of employees, clients, contractors and the general public at all times, whilst minimising any impact on the environment as a direct or indirect result of our activities. It is the policy of management to ensure that the quality requirements of the company meet or exceed all of our customers’ needs and to continually improve the effectiveness of our quality system. We maintain a quality management system to meet requirements of the ISO 9001: 2008 standard. It is our goal to manufacture quality products that exceed the expectations of our customers.

|

Company Values

The values of a company are extremely important. Key to the company values of Bignall Group are:

- Honesty, integrity and trust.

- Growing local employment and doing something good in the community.

- The highest levels of customer service and quality.

If you would like to find out more about Masterlube or any of the Bignall Group companies, please get in touch: msl@bignall.co.uk

Online Payments

Pay securely using PayPal or Credit Card if you have an order number.

Simply enter your order number, amount, CLICK CONTINUE, then decide if you wish to pay via card or PayPal.